In recent years, China has discovered and developed a series of deep or ultra-deep carbonate reservoirs. These reservoirs are characterized by their depth, high formation temperature,substantial reservoir thickness, severe heterogeneity, high carbonate purity in the matrix, and low natural production rates. Acidizing is a crucial production enhancement method for such reservoirs, and the performance of acidizing fluids directly affects the acidizing results. Therefore, these reservoirs demand higher requirements for acidizing fluid systems.

The key factors influencing the effectiveness of conventional acidizing treatments are the effective length and the diversion capability of acid-etched fractures after acidizing. The effective length of acid-etched fractures is critical for the acidizing transformation of tight carbonate reservoirs. Effectively achieving longer acid-etched fractures has been a long-standing challenge in acidizing technology.

To address this challenge, our company has developed novel acidizing fluid systems that gradually move towards multi-performance characteristics, including high-temperature resistance, filter loss reduction, slow acidizing, corrosion inhibition, low friction, and easy flowback. These developments led to the creation of larger-scale acid-etched fractures and improved diversion capability.

①Autogenic Acid System: This slow acid liquid system produces reactive acids through chemical reactions in downhole conditions to enhance deep formation permeability.

②Gelled Acid System: This method involves adding a gelling agent to the acid solution,increasing its viscosity, slowing down the diffusion and mass transfer of H+ ions, thereb achieving slow acidizing and filter loss reduction, extending the reach of acid treatment, and enabling deep formation acidizing.

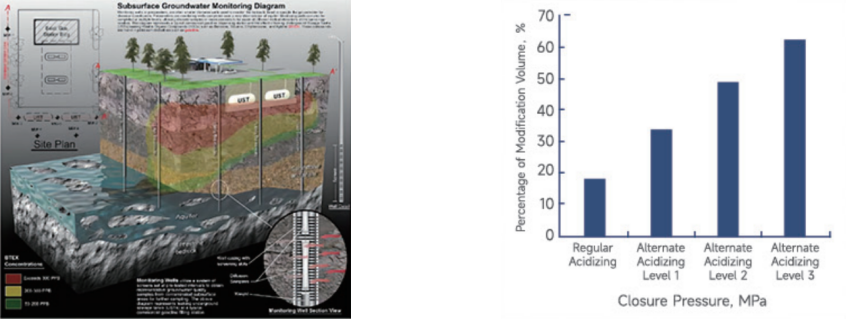

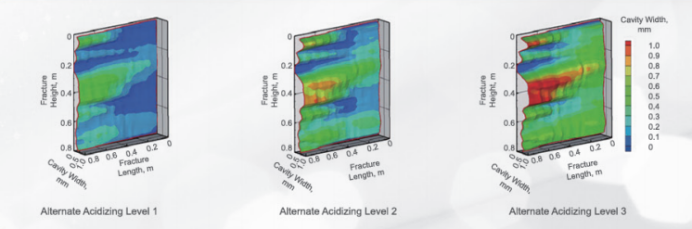

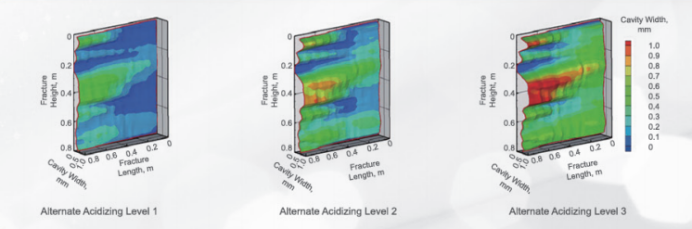

③Autogenic Acid + Gelled Acid System: Typically, an alternating acidizing pattern is adopted.As the number of alternating cycles increases, the communication range of the vertical fracture center, top, and bottom significantly expands, spreading laterally, and the entire fracture body widens in the width direction, piercing through the entire formation model.