- Products & Services

- Case Studies

-

Investor Relations

Amplify Our Impact, Harness Collective StrengthUnite in strength and collaboration, and become our most trusted allyLearn MoreAmplify Our Impact, Harness Collective StrengthUnite in strength and collaboration, and become our most trusted allyLearn More

-

Career Opportunities

Amplify Our Impact, Harness Collective StrengthDiscover who we are, become part of our journey, and together, let's shape a better tomorrow.Learn MoreAmplify Our Impact, Harness Collective StrengthDiscover who we are, become part of our journey, and together, let's shape a better tomorrow.Learn MoreAmplify Our Impact, Harness Collective StrengthDiscover who we are, become part of our journey, and together, let's shape a better tomorrow.Learn MoreAmplify Our Impact, Harness Collective StrengthDiscover who we are, become part of our journey, and together, let's shape a better tomorrow.Learn More

-

News

Amplify Our Impact, Harness Collective StrengthStay abreast of our recent corporate developmentsLearn MoreAmplify Our Impact, Harness Collective StrengthStay abreast of our recent corporate developmentsLearn More

-

Sustainability

Amplify Our Impact, Harness Collective StrengthZero in on the forefront of green tech, stay updated on the latest in environmental innovations, and discover our most recent strides in sustainable development.Learn MoreAmplify Our Impact, Harness Collective StrengthZero in on the forefront of green tech, stay updated on the latest in environmental innovations, and discover our most recent strides in sustainable development.Learn MoreAmplify Our Impact, Harness Collective StrengthZero in on the forefront of green tech, stay updated on the latest in environmental innovations, and discover our most recent strides in sustainable development.Learn MoreAmplify Our Impact, Harness Collective StrengthZero in on the forefront of green tech, stay updated on the latest in environmental innovations, and discover our most recent strides in sustainable development.Learn More

-

About Us

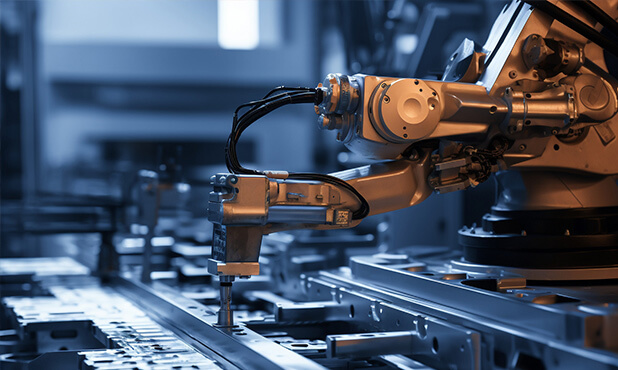

One-stop Oil & Gas Production Enhancement Service ProviderSichuan Wewodon Petroleum Technology Co., Ltd. stands as a beacon in technology-driven services for the oil and gas sector.Learn MoreOne-stop Oil & Gas Production Enhancement Service ProviderSichuan Wewodon Petroleum Technology Co., Ltd. stands as a beacon in technology-driven services for the oil and gas sector.Learn MoreOne-stop Oil & Gas Production Enhancement Service ProviderSichuan Wewodon Petroleum Technology Co., Ltd. stands as a beacon in technology-driven services for the oil and gas sector.Learn MoreOne-stop Oil & Gas Production Enhancement Service ProviderSichuan Wewodon Petroleum Technology Co., Ltd. stands as a beacon in technology-driven services for the oil and gas sector.Learn MoreOne-stop Oil & Gas Production Enhancement Service ProviderSichuan Wewodon Petroleum Technology Co., Ltd. stands as a beacon in technology-driven services for the oil and gas sector.Learn MoreOne-stop Oil & Gas Production Enhancement Service ProviderSichuan Wewodon Petroleum Technology Co., Ltd. stands as a beacon in technology-driven services for the oil and gas sector.Learn More